Technology

As electrification accelerates across mobility, renewable energy, and industrial systems, Hillcrest Energy Technologies is offering a smarter path forward. Our proprietary Zero Voltage Switching (ZVS) inverter technology unlocks new levels of efficiency, performance, and integration — all while reducing complexity and cost.

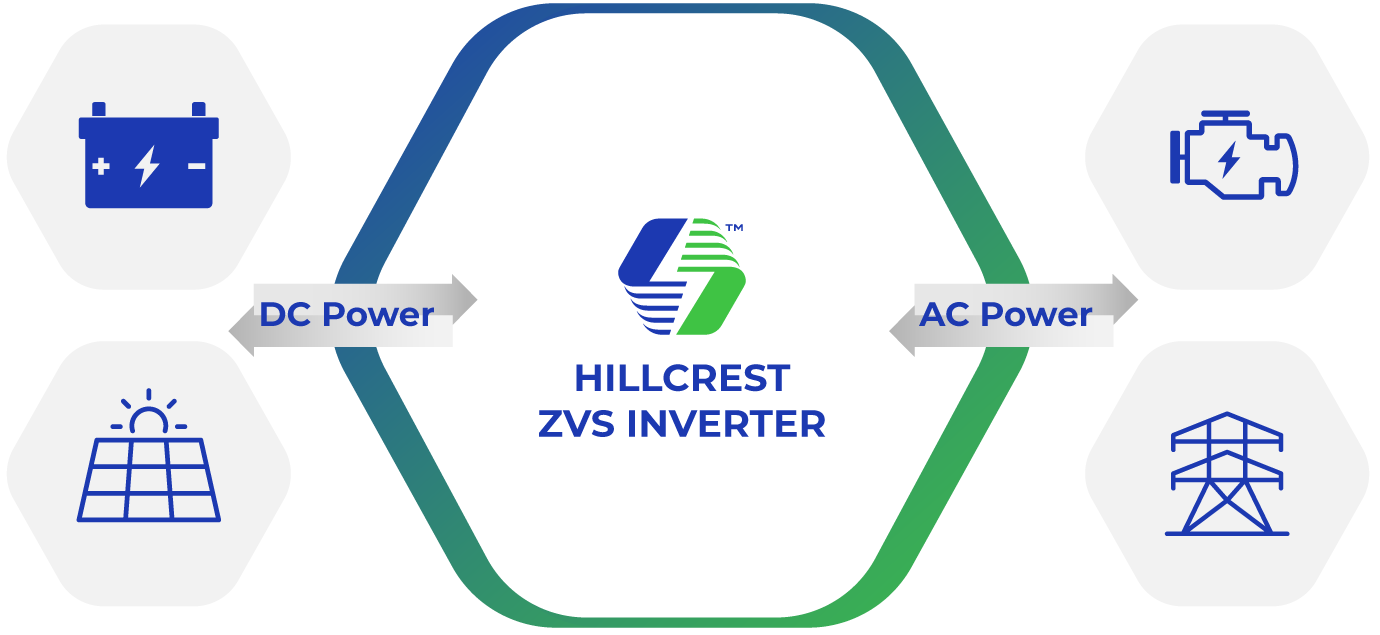

Inverters are the backbone of modern electrified systems. Whether in electric vehicles, grid-connected renewables, or industrial drives, they’re tasked with efficiently converting DC to AC power — faster, cleaner, and in more compact packages than ever before.

Hillcrest’s ZVS inverter platform is engineered to meet these demands by improving not just component-level performance, but the entire power conversion system.

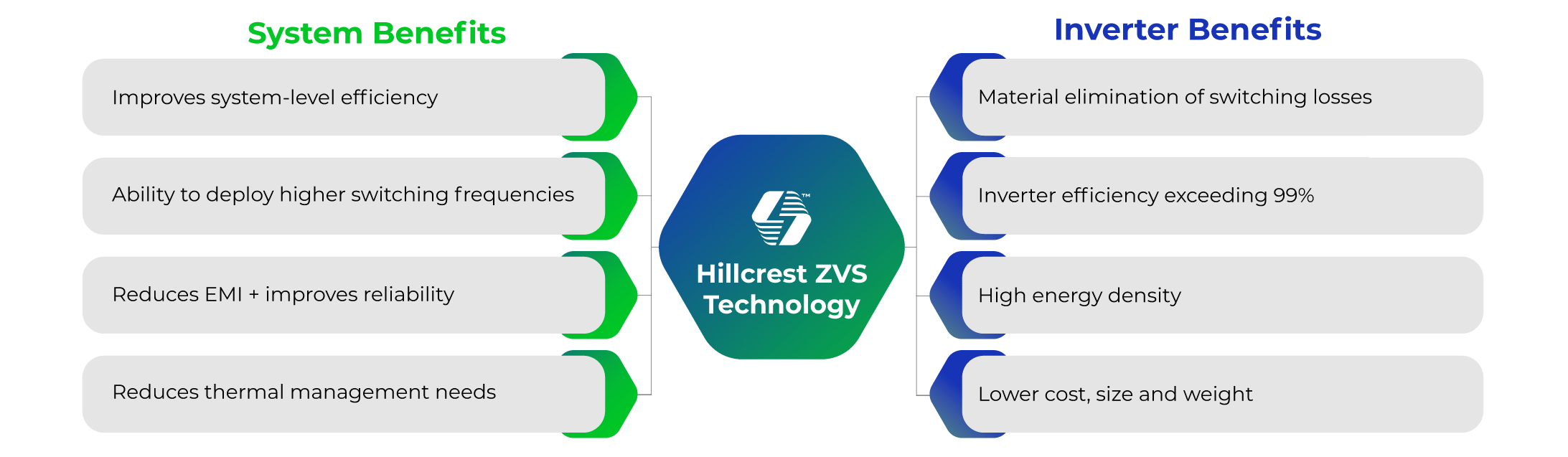

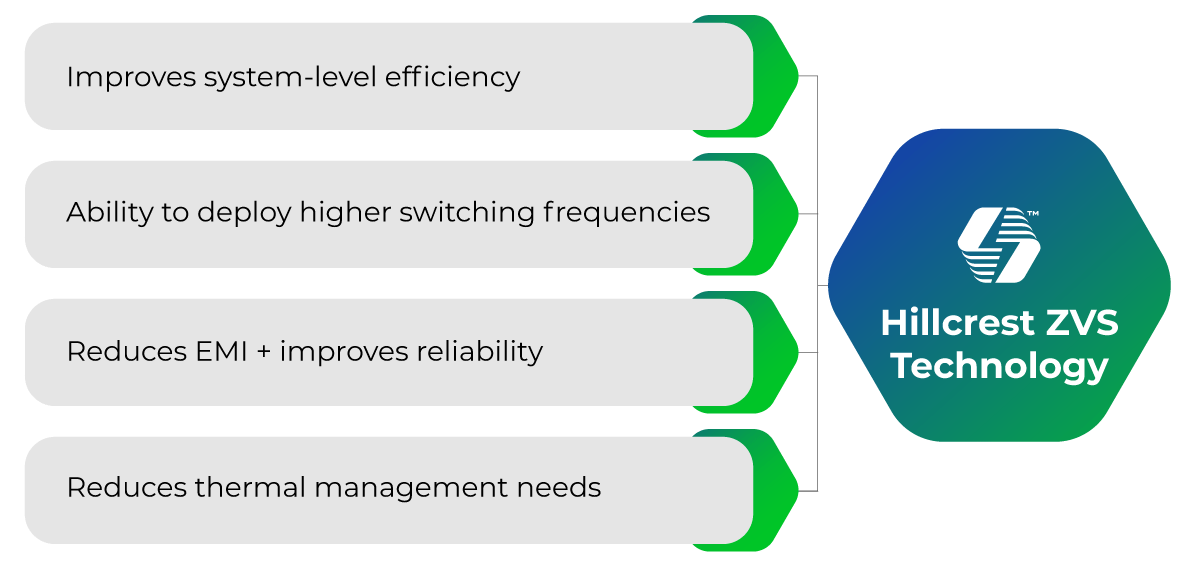

System Benefits

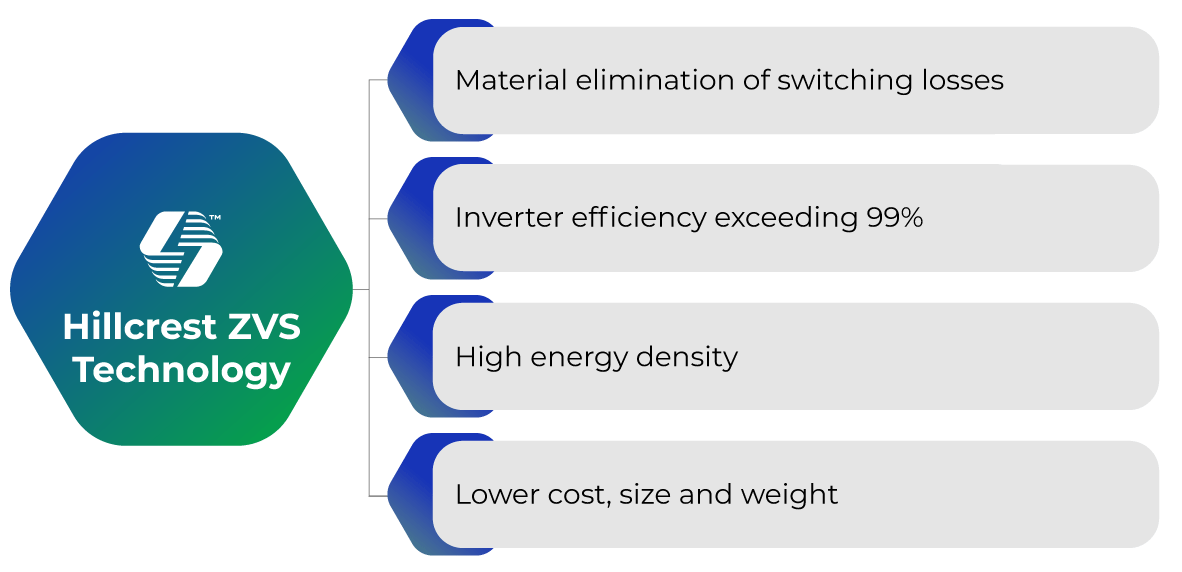

Inverter Benefits

The Challenge with Conventional Power Conversion

Wide bandgap (WBG) semiconductors like silicon carbide (SiC) and gallium nitride (GaN) have opened the door to smaller, faster, and more efficient inverters. They enable higher switching frequencies, better thermal performance, and more compact system footprints.

But WBG alone isn’t a complete solution. High-speed switching introduces new challenges, including:

- Increased EMI

- Persistent switching losses under hard-switching conditions

- Complex multilevel architectures

- Higher harmonic content and filtering requirements

That’s where Hillcrest’s ZVS technology comes in.

ZVS Technology: High efficiency, minimal switching losses

%

Inverter efficiency

- Materially eliminates switching losses

- Enables higher switching frequencies without increasing semiconductor temperatures

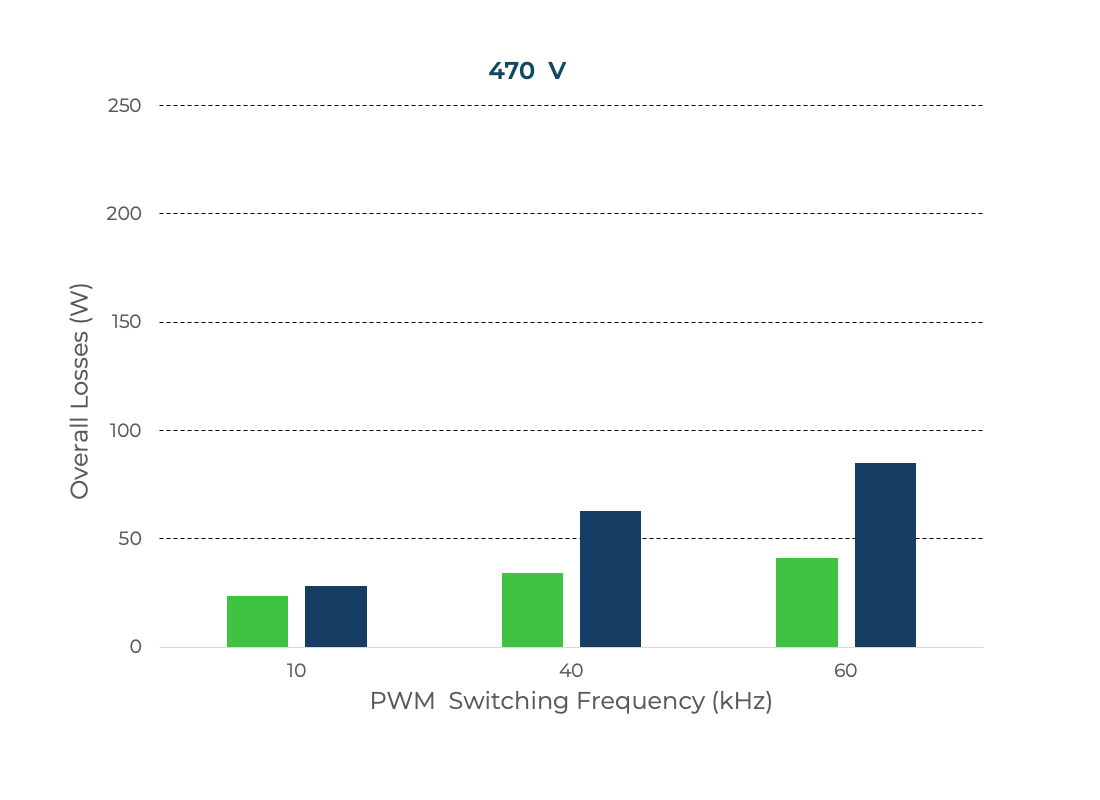

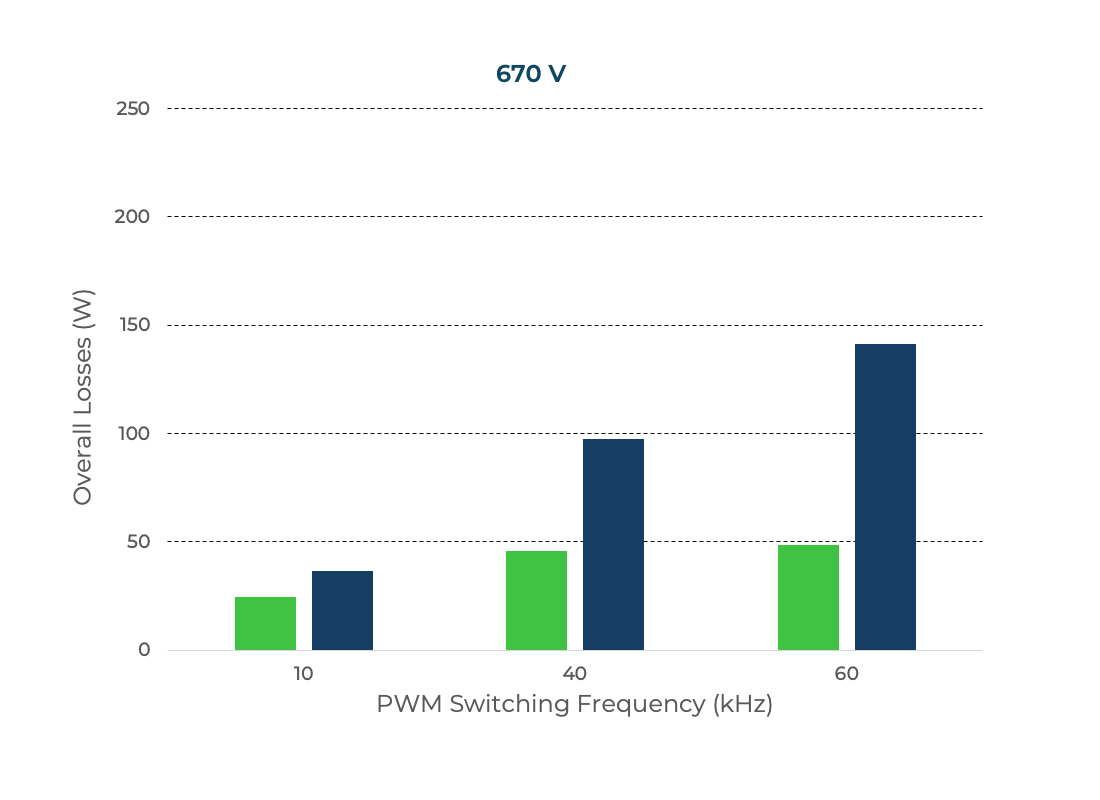

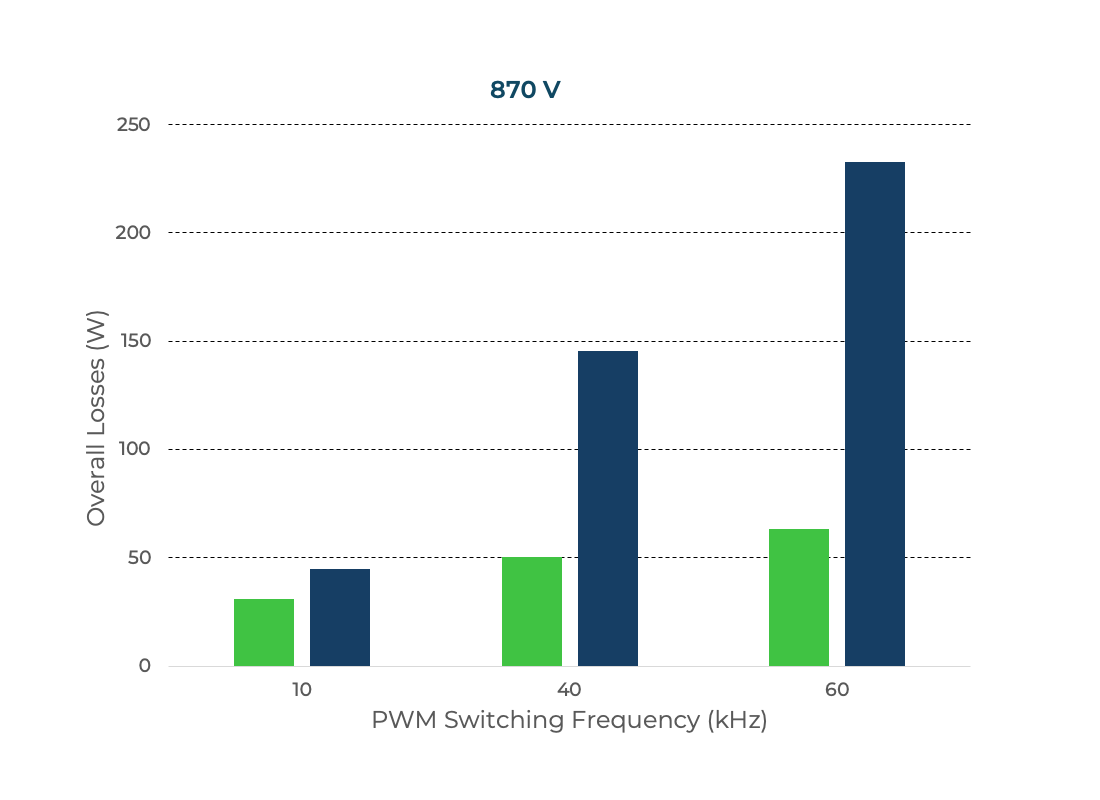

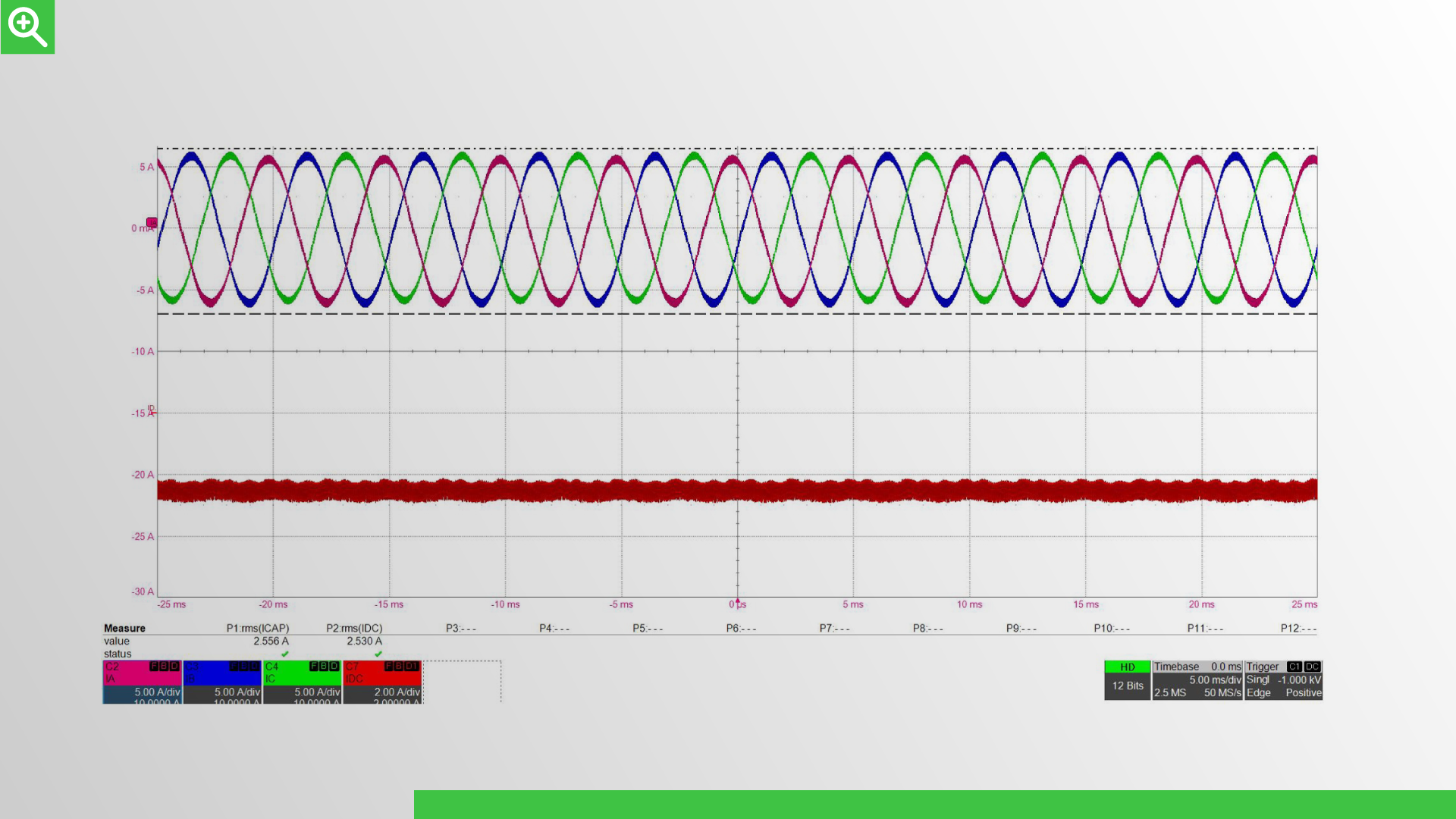

Inverter Efficiency Comparison

- The inverters are operated at 470V, 670V and 870V

- Partial load (5A, 14.7kV/µs) is used for comparison as conventional inverter could not achieve full load at higher voltage levels

- Measurements were made at 10 kHz, 40 kHz, and 60 kHz at each voltage

- The inverters are operated at 470V, 670V and 870V

- Partial load (5A, 14.7kV/µs) is used for comparison as conventional inverter could not achieve full load at higher voltage levels

- Measurements were made at 10 kHz, 40 kHz, and 60 kHz at each voltage

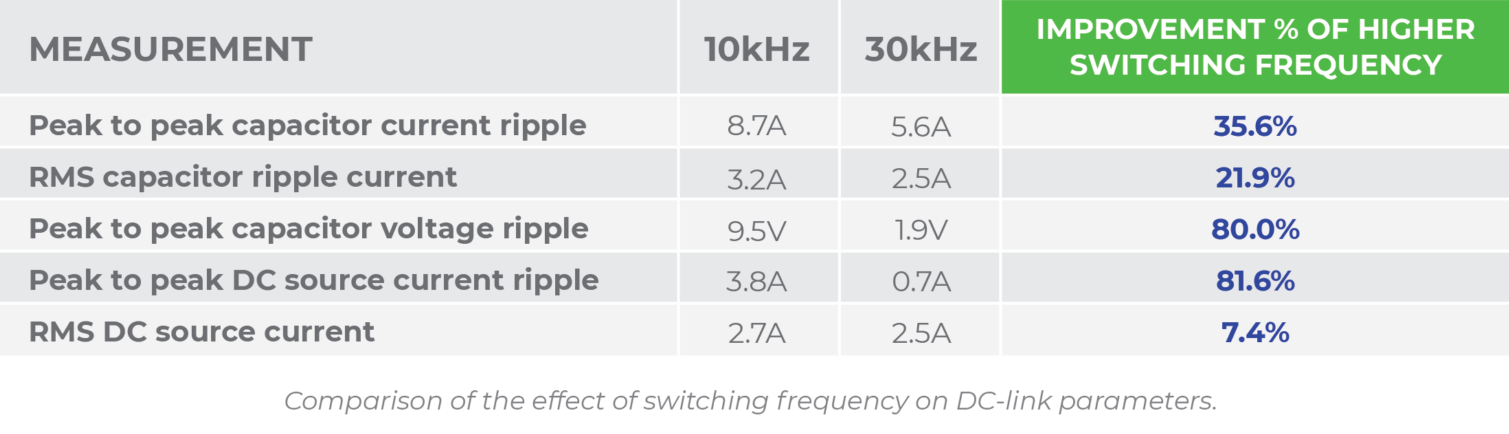

System-Level Cost Benefits

ZVS doesn’t just improve performance — it delivers meaningful cost savings across the system:

- Lower SiC chip area requirements mean lower semiconductor material costs

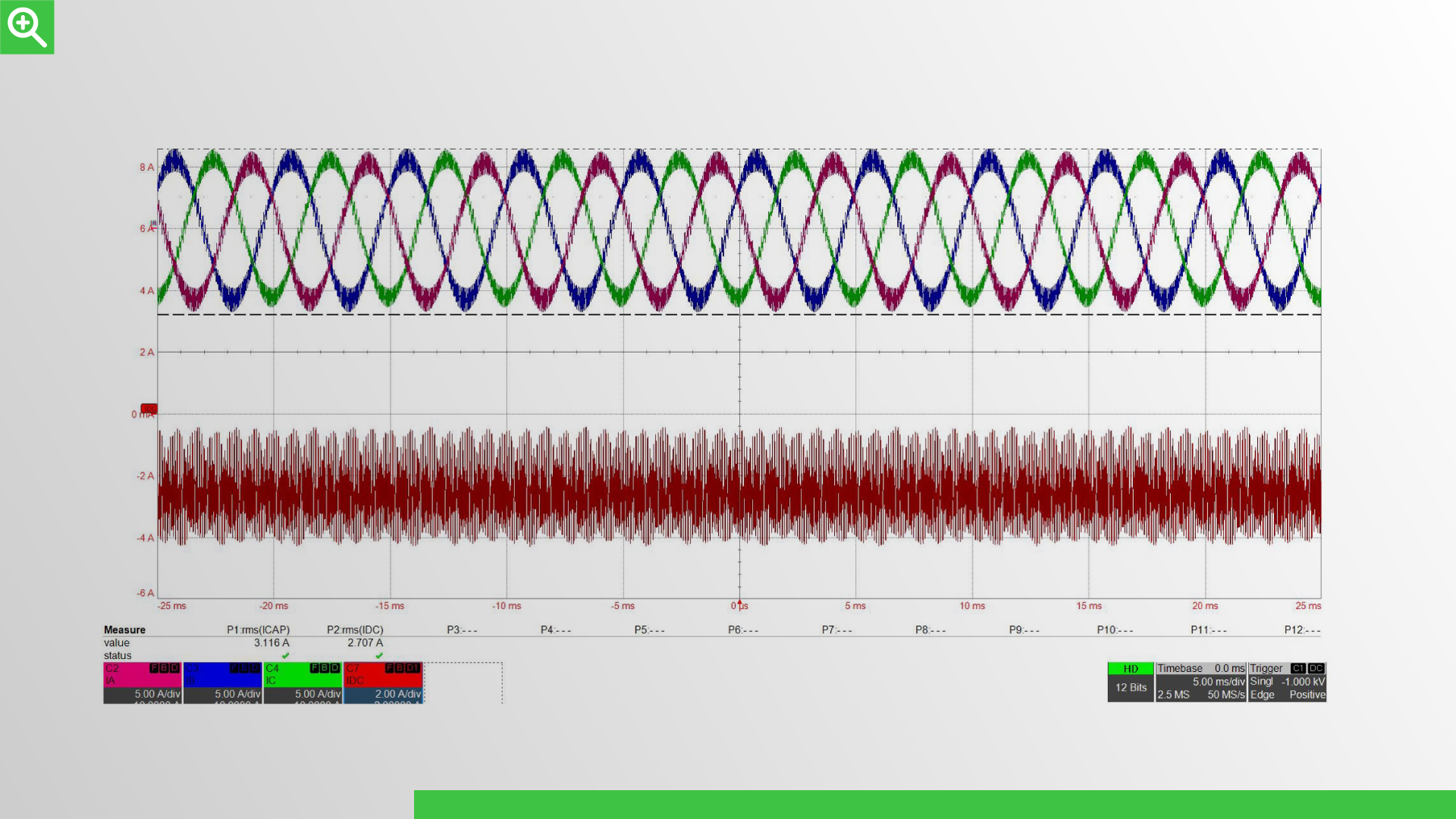

- Reduced DC-link capacitance allows for smaller, less expensive capacitors

- Minimized EMI and harmonic content reduce the need for oversized filters and shielding

These benefits add up to simpler, lighter, and more cost-effective power systems.

Integration Made Easy

ZVS was engineered with real-world design constraints in mind. Our architecture allows OEMs and system developers to:

- Retain their existing control strategies

- Integrate ZVS without rethinking the entire system

- Retrofit into existing inverter designs

With its flexible, application-agnostic design, ZVS accelerates innovation without adding development burden.

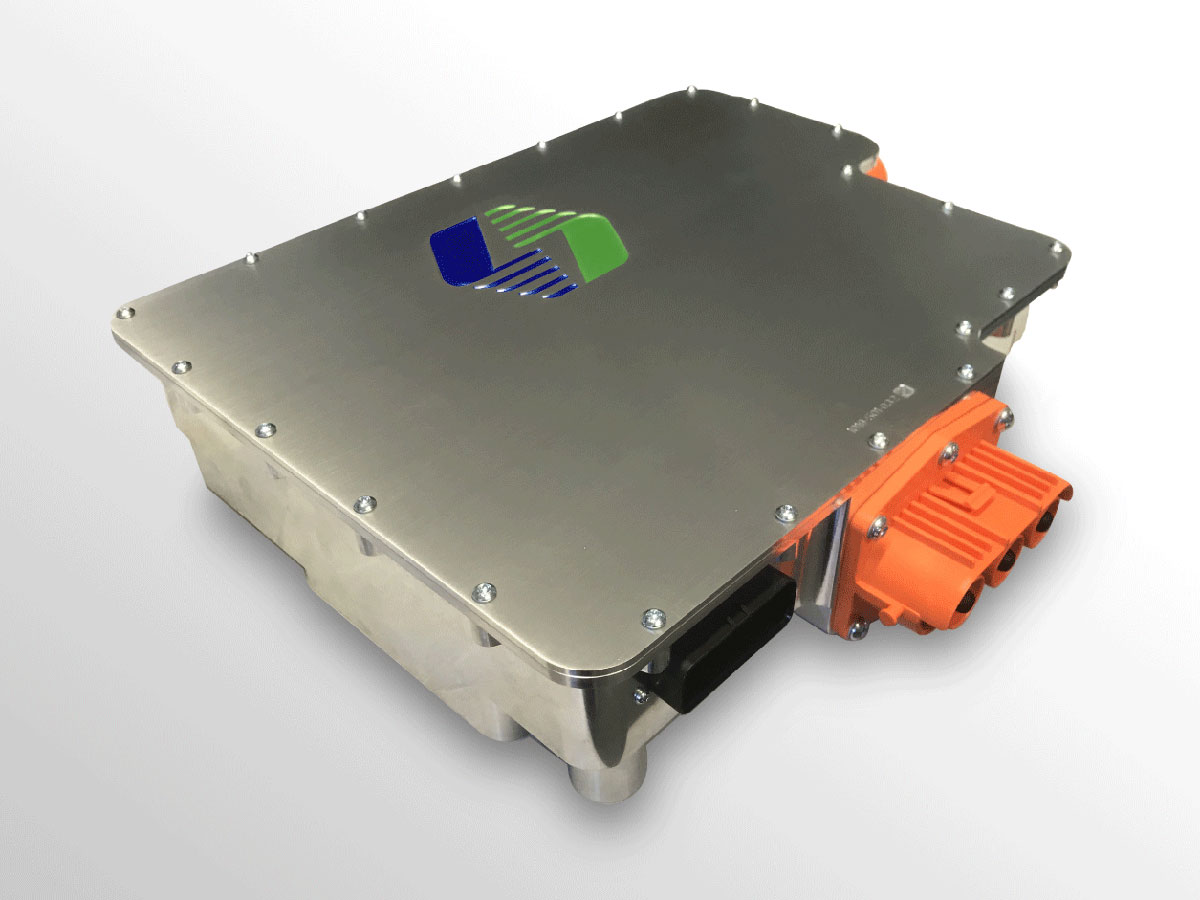

EV Traction Inverter

Hillcrest ZVS Technology

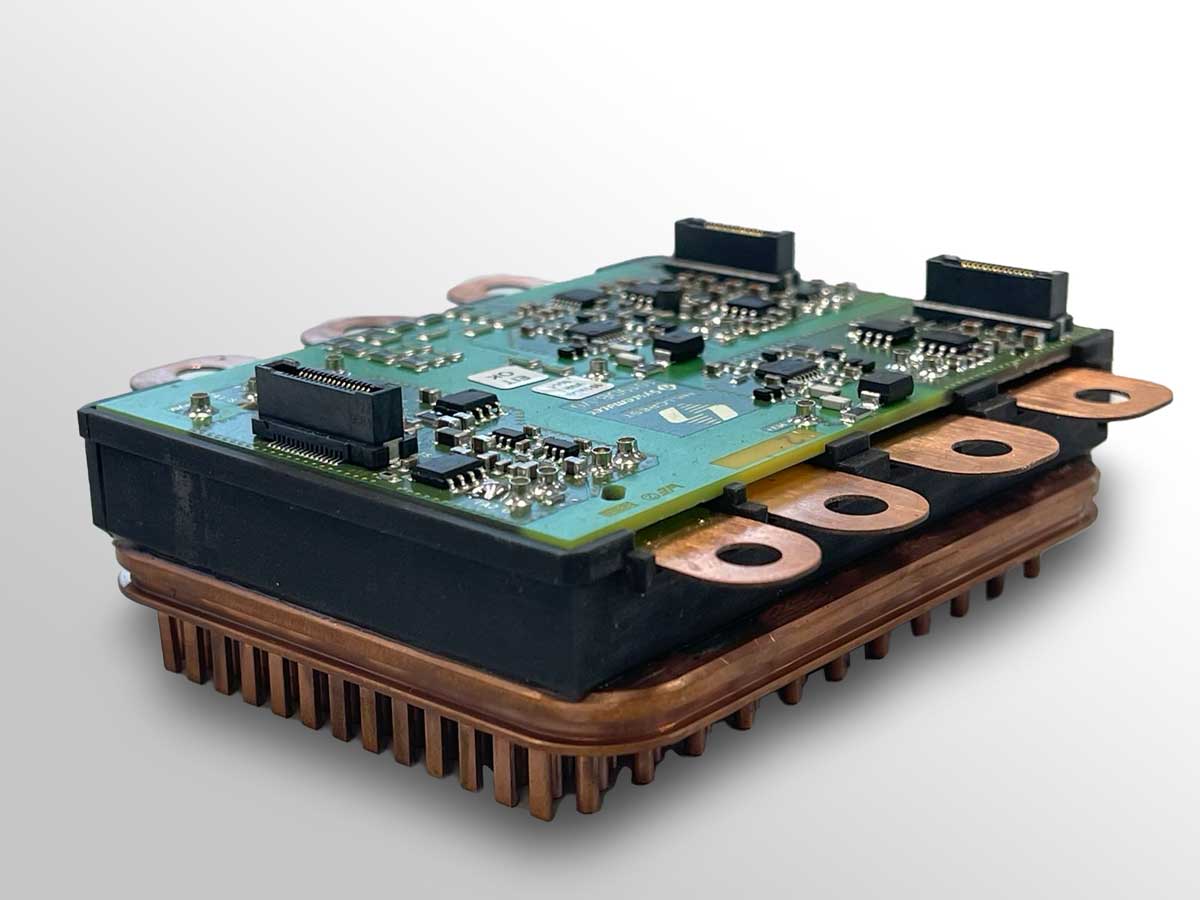

ZVS Power Module

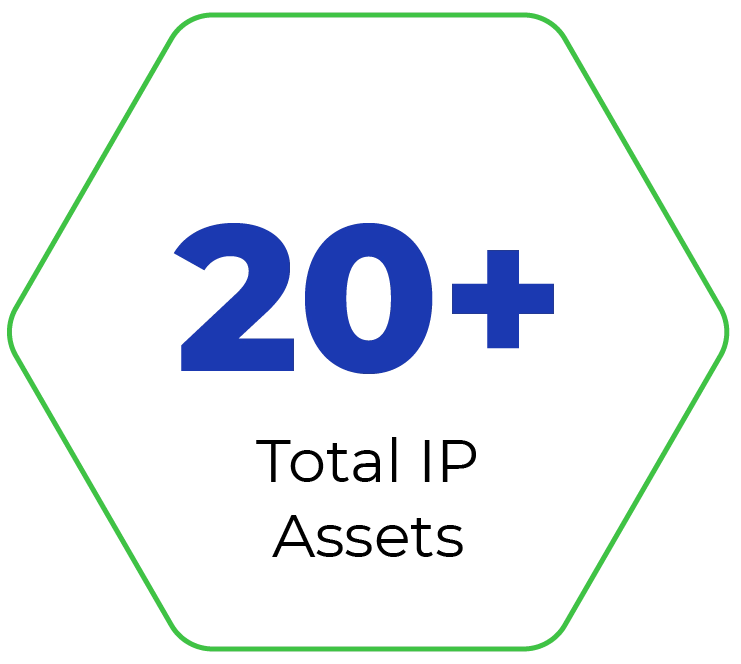

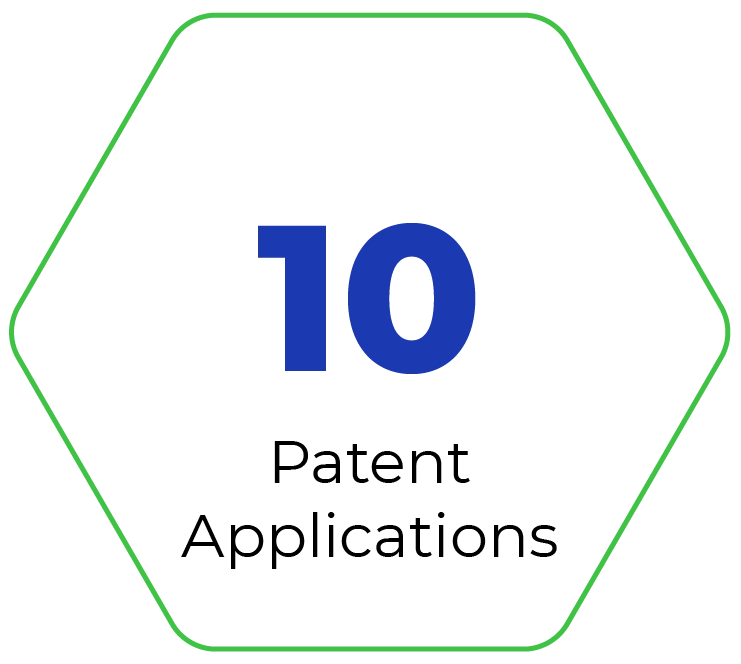

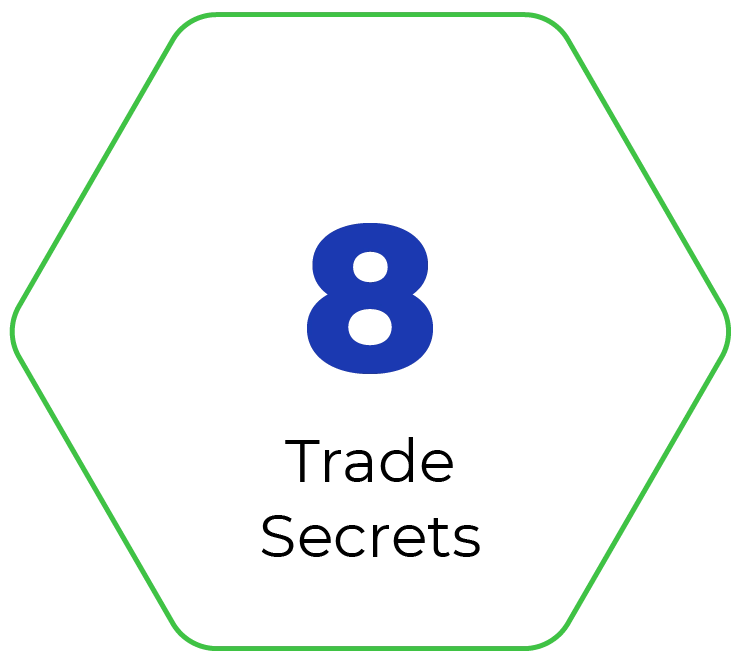

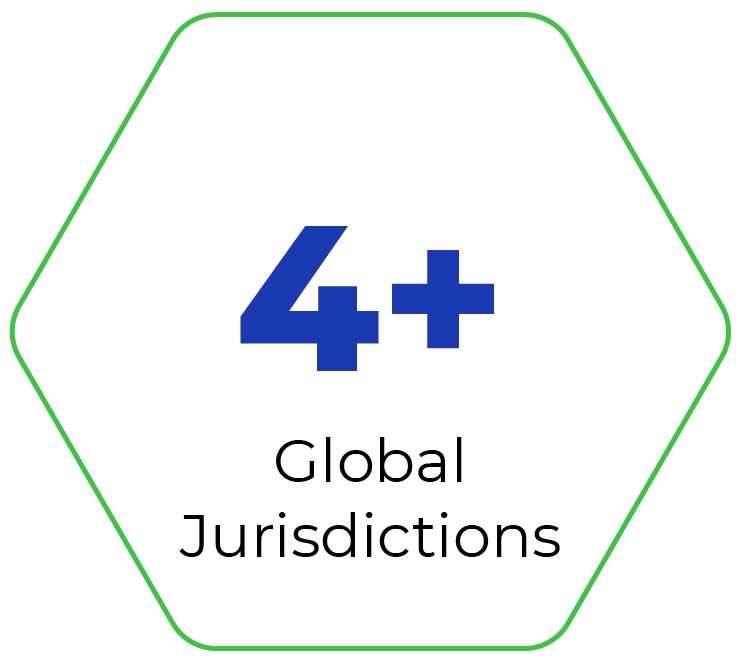

Intellectual Property Portfolio

ZVS Technology Moat

Hillcrest has developed a comprehensive IP strategy for its ZVS Technology. This multi-layered protection creates significant barriers to competitive replication across multiple power conversion product categories.

Power Conversion, Reimagined

At Hillcrest, we believe the future of power conversion lies in system-level optimization. Our ZVS platform empowers designers to meet rising performance demands while reducing cost and complexity — all with seamless integration into today’s architectures.

Whether you’re electrifying a drivetrain, stabilizing a grid, or developing next-generation energy storage, ZVS delivers efficiency without compromise.

Want to know more? Let’s connect!

Fill out the form below to directly download our technical white paper.

Fill out the form below to directly download our technical white paper.