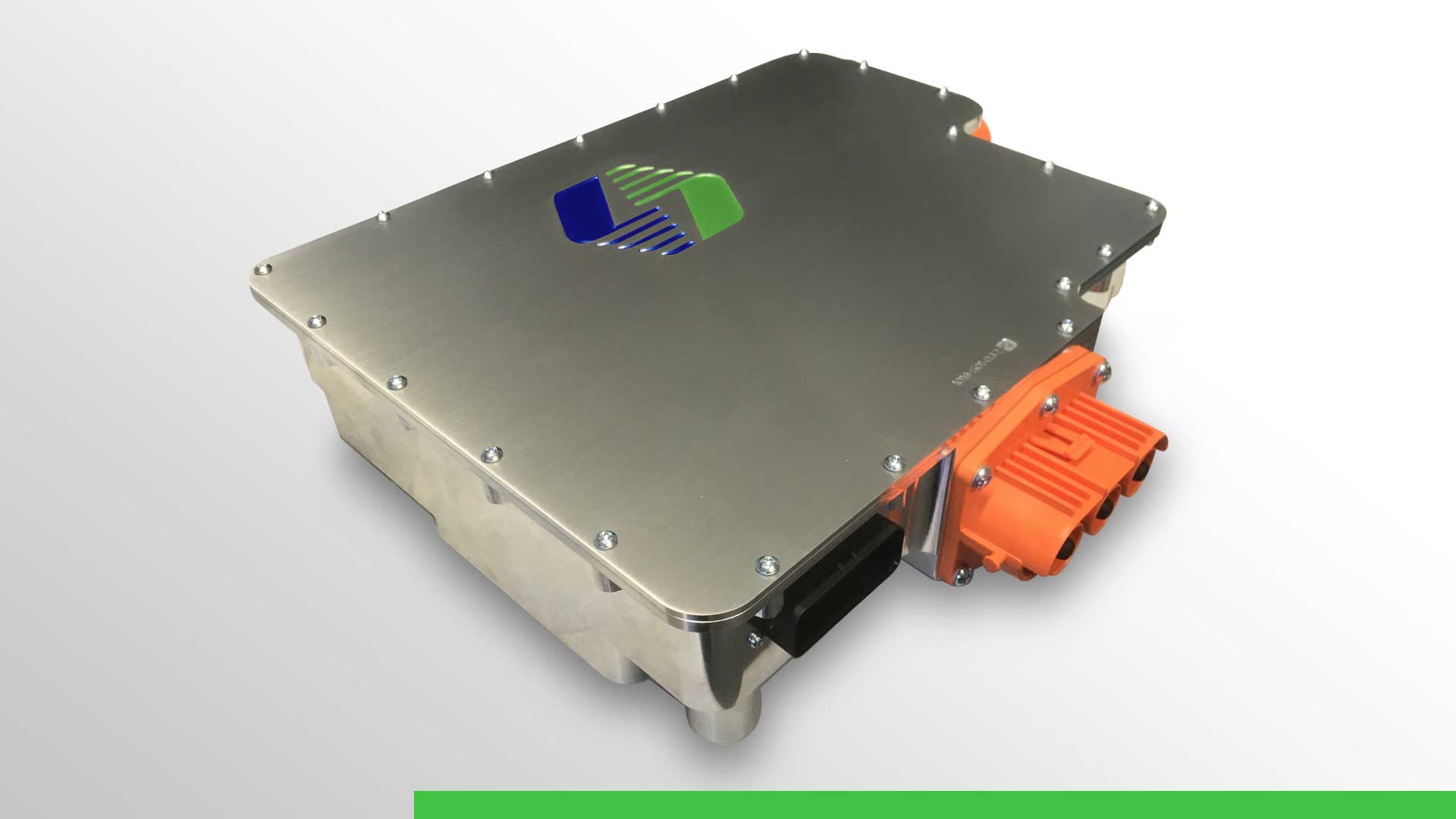

EV TRACTION INVERTER PROTOTYPE

Revolutionizing Power Conversion at the Heart of the EV Powertrain

The traction inverter is the central nervous system of any electric vehicle, converting DC power from the battery into the AC power needed to drive the motor. Positioned at the intersection of performance, efficiency, and cost, it remains a critical focus for next-generation EV innovation.

At Hillcrest, we’ve reimagined what an inverter can do. Our 1000V | 350 kVA SiC traction inverter prototype integrates our proprietary Zero Voltage Switching (ZVS) Technology, enabling power applications to operate at both higher power levels and higher switching frequencies—without sacrificing efficiency.

Why It Matters:

Conventional inverters face a tradeoff between power density, efficiency, and thermal performance. Hillcrest’s ZVS-based inverter addresses these limitations head-on:

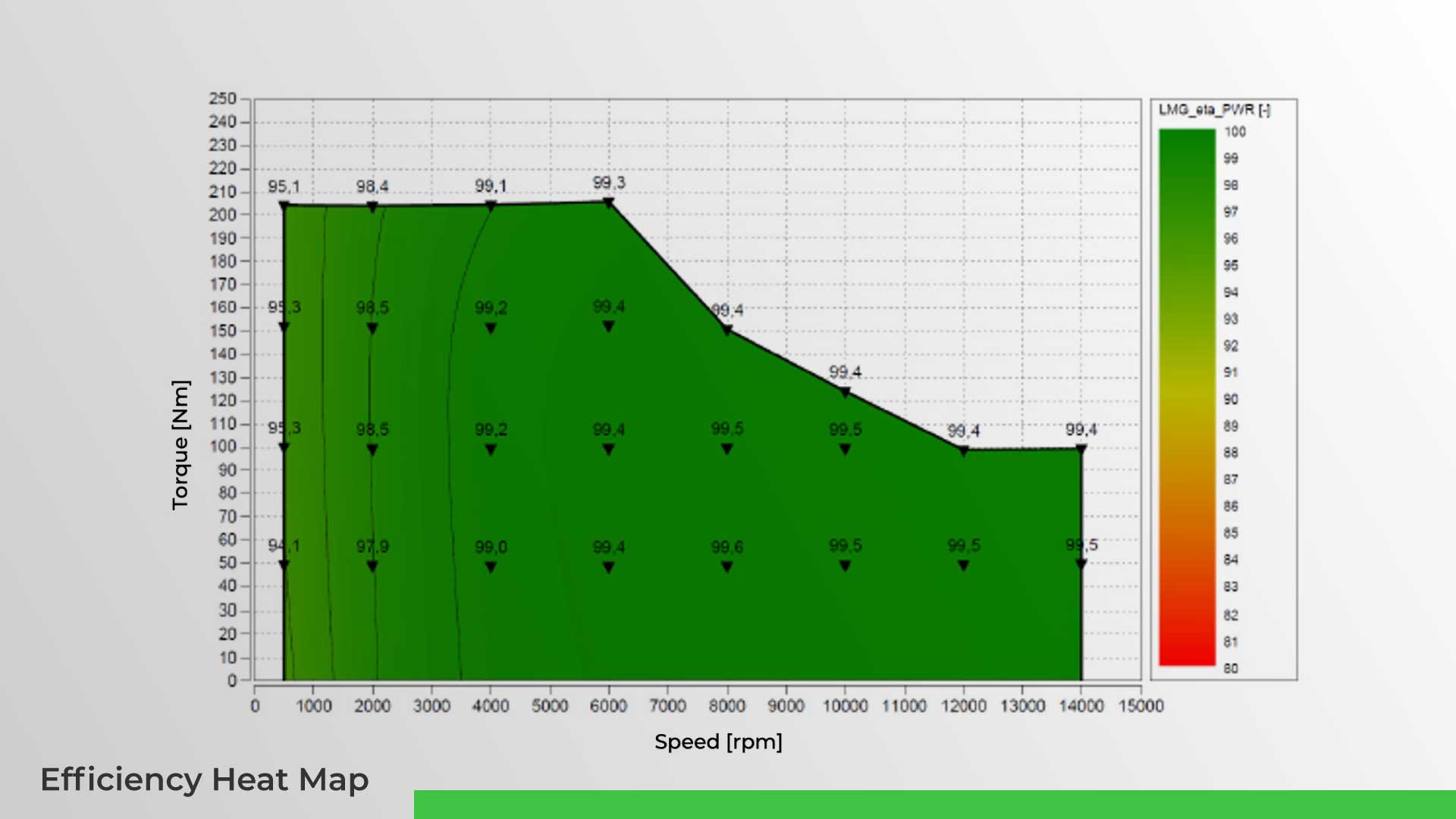

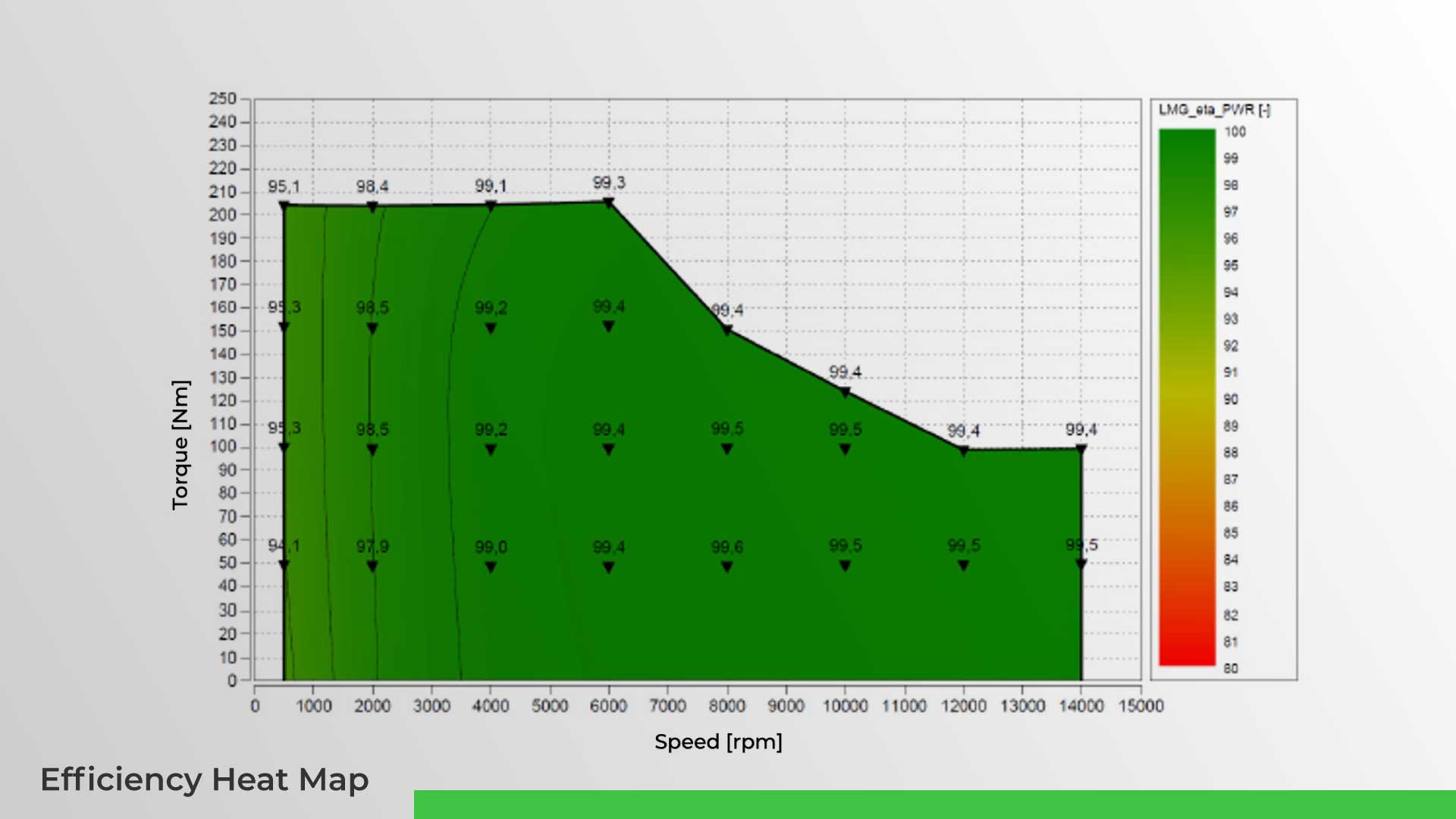

- Unmatched Efficiency: Delivers industry-leading inverter efficiency of up to 99.7%, virtually eliminating switching losses.

- Reduced Heat Generation: Operates cooler, enabling simpler and more cost-effective thermal management solutions.

- Compact and Lightweight: Smaller form factor means less weight and more design flexibility for OEMs and system integrators.

- Lower EMI: Ultra-low electromagnetic interference allows for easier compliance and less shielding, reducing overall system cost.

Built for the Next Generation of Electric Vehicles

Key Features:

Operating Input Voltage Range

400-940 VDC

Maximum Electrical Efficiency

Up to 99.7%

Nominal Voltage

800 VDC

Efficient Semiconductor Utilization

2.5mm2/kW

Continuous RMS AC Output Current

350 A

Power Devices

3 SiC modules

Peak RMS AC Output Current

400 A

HV Bus Capacitance

135 uF

Control Input Supply Voltage Range

9 -16 VDC

Ambient Temperature

-40°C…100°C

Nominal PWM Switching Frequency

50 kHz

Coolant Temperature (liquid cooling)

-40°C…70°C

Nominal Power Density

>50 kW/L

Communication

1 x CANbus

1 x RS422

Control Type

Current / Speed with Field Weakening and MTPA

Digital Input

>1 Digital Input

Motor Feedback

Resolver or Sin/Cos Encoder